Rubber vulcanizing Tester warehouse|Rubber Standards : agency This test method covers the use of the oscillating disk cure meter for determining selected vulcanization characteristics of vulcanizable rubber compounds. Resultado da AO VIVO: TV ATALAIA - CAJU CAP. Comments. Most relevant Elouise Carolina · 1:44. Dia 20 12. 2y; Elouise Carolina · 1:29. Esse não é o de .

{plog:ftitle_list}

10 de mai. de 2022 · Summary. Hi, I’m Kaleb, a freshmen in college. I have no friends so I joined a club with three other girls. I wonder how my life’ll be now..

An advanced and fully automated rubber testing solution for high capacity manufacturers of rubber compounds. Download Brochure Request Quote.The P-VS 3000 universal cutter generates consistent test samples for multi-blade .Proper tensile testing of vulcanized (durable) rubber and thermoplastic elastomers per ASTM D412 is quite useful since these compounds are one of the most complex and universally used .Rubber Standards. ASTM's rubber standards are instrumental in specifying, testing, and assessing the physical, mechanical, and chemical properties of a wide variety of materials and .

This test method covers the use of the oscillating disk cure meter for determining selected vulcanization characteristics of vulcanizable rubber compounds.Measure temperatures within the core of the rubber product in rubber vulcanization process with Datapaq MonoPaq2 Thermal Profiling System.Rubber test mixes — Preparation, mixing and vulcanization — Equipment and procedures 1 Scope This International Standard specifies the equipment and procedures for the preparation, .We provide a detailed explanation of the Rubber Vulcanization Process, including the role of the vulcanizing agent, temperature control, and reaction mechanisms.

1.1 These test methods cover procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers. These methods .The P-VS 3000 universal cutter generates consistent test samples for multi-blade cutting knives or rough materials requiring high cutting forces. Customizable with over 30 die options, the cutting force can be preset, ensuring precisely cut .Rubber, vulcanized or thermoplastic — Antistatic and . ISO 18899:2013, Rubber — Guide to the calibration of test equipment 3 Terms and definitions . to use the conditions prevailing in the factory, warehouse or laboratory, provided that the relative humidity is not more than 70 %.Hydraulic Vulcanizing Press Machine, Rubber Plate Vulcanization Machine Instruction: Rubber Vulcanizing Press Machine is placed in the casting mold and clamped between the electric-heating flat plates to apply pressure and .

Standard Test Methods for Vulcanized Rubber and Thermoplastic

In this chapter we will direct out attention to the test procedures and instruments used to measure two of the most critical properties of rubber and rubber compounds, processibility and vulcanization.These characteristics are vitally important because they define the operating window available for converting uncured rubber compound into a usable product.

Learn about Rubber compounding: https://youtu.be/yK6-QNB1roo?si=jzlrsKFDhkssuCTpThis video explains the basics of the rubber vulcanization process, including.5.1 This test method is used to determine the vulcanization characteristics of (vulcanizable) rubber compounds. 5.2 This test method may be used for quality control in rubber manufacturing processes, for research and development testing of raw-rubber compounded in an evaluation formula-tion, and for evaluating various raw materials used in .

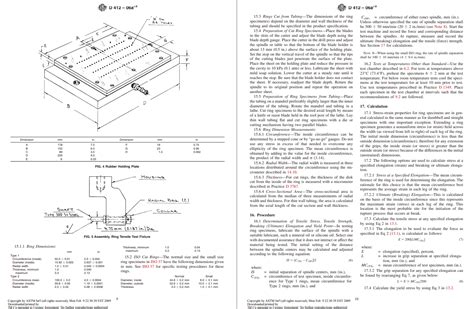

PROCESSING AND VULCANIZATION TESTS 109 DIE RUBBER LOWER DIE ROTOR Fig. 4.2. Mooney chamber and rotor. flow) during the test are indicated by a low plasticity number. . Standard gives standard test conditions for raw rubber viscosity measurements. Results of a typical test are normally reported as follows: 50-ML 1 + 4 (100°C) where 50-M is . Discovered by American chemist Charles Goodyear in 1839, vulcanization is a chemical process that transformed the rubber industry. The technique, which involves combining rubber with other materials, turns natural rubber into a durable, elastic material with many practical applications. Another term for vulcanization is “cure”. The story and science behind one of the most important developments in polymer science. How is vulcanized rubber made? Why is it important? In what applicati.Worker placing a tire in a mold before vulcanization. Vulcanization (British English: vulcanisation) is a range of processes for hardening rubbers. [1] The term originally referred exclusively to the treatment of natural rubber with sulfur, which remains the most common practice.It has also grown to include the hardening of other (synthetic) rubbers via various means.

Rubber test mixes — Preparation, mixing and vulcanization

SKZ131 ASTM D5289 ISO6502 Rotor-less Curemeter Rubber Vulcanizing Tester-Cure Meter. For measuring the unvulcanized rubber traits to discover the best therapy time. Standard: ASTM D5289, ISO6502, T30,T60,T90. Technical parameters:

METHODS OF TEST FOR VULCANIZED RUBBER PART 1 DETERMINATION OF TENSILE STRESS-STRAIN PROPERTIES ( Third Revision ) IS 3400 (Part 1) : 2012 ISO 37 : 2011 1. 3.2 elongation E tensile strain, expressed as a percentage of the test length, produced in the test piece by a tensile stress 3.3Mooney Viscosity. The Mooney Viscosity test is a well-established method for characterizing uncured rubber materials. Following well- defined standard procedures, the sample is preheated for a defined period, then sheared at a constant rate.The Mooney Viscosity is recorded from the end of this deformation stage. in the present example, the outstanding precision of the MVone .

so hard to book behind the wheel test

on the shape of the test piece. The rubber-to-metal bond is sometimes subjected to a combination of stresses (see Figure 1). . Based on ASTM D 429 and DIN 53531, a rubber coating is vulcanized onto a 240 x 25 x 6 mm metal strip , and then peeled off at an angle of 90° at a rate of 50 mm/min. This test, corresponding closely to .vulcanization of rubber test mixes specified in the various International Standards for the evaluation of such test mixes. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies.

The vulcanization requires quite a lot of resin: 5–12 phr, together with some parts SnCl 2.2H 2 O as a Lewis acid. The vulcanization proceeds rather slow, but good compression sets are obtained and very good thermal properties. Resin vulcanization of IIR is especially applied in the manufacturing of bladders for tire vulcanization. An international standard, ISO 2921:2019 – Rubber, Vulcanized – Determination Of Low-Temperature Characteristics – Temperature-Retraction Procedure (TR Test), helps test vulcanized rubber. Vulcan is the Roman .K-12 Lesson Plan: Because polymers are such large molecules, the intermolecular forces between polymer chains are stronger than most other organic substances. Rubber, despite our general suppositions on how phases of matter should behave, is a liquid at room temperature (it will flow over time). Due to the strong intermolecular forces present (van der Waal .

By Ann Marie Somma. Charles Goodyear’s discovery of the vulcanization of rubber—a process that allows rubber to withstand heat and cold—revolutionized the rubber industry in the mid-1800s.Automotive tires, pencil erasers, life jackets, balls, gloves, and more are all in commercial use because of Goodyear’s relentless experimentation to unlock the .Making Rubber Stronger Through Vulcanization. Rubber is a polymer of isoprene that is formed with double bonds between each of the individual monomers (or units). In simple terms, one of these bonds is flexible and can allow the polymer to take up many shapes and sizes, which is what basically gives rubber its property of elasticity. Vulcanization of rubber uses heat and sulfur (or another chemical) to form a hardened cross-linked polymer. Vulcanization or vulcanisation (British) is a process of hardening rubber using chemicals and (usually) heat. Originally, vulcanization described the treatment of natural latex rubber with heat and sulfur.While this remains the most common type of .

Rubber Vulcanization Process

ratio of the loss in volume of a standard rubber to the loss in volume of a test rubber measured under the same specified conditions and expressed as a percentage [SOURCE: ISO 23794:2015, 3.3] 3.4 slip rate ratio of the difference between the circumferential speed of the test piece and that of the abrasion A Beginner's Guide to Rubber: Rubber Vulcanization. There are many ways to form rubber parts, part 3 of this guide will discuss the remaining more popular processes used in the industry today. As mentioned earlier, the process for turning rubber compounds into usable finished products is vulcanization. There are various types of vulcanization .

Potential employees can watch to find out what kind of work environment Custom Rubber offers and see the type of work. Custom Rubber Corp. is now hiring, .85 starting wage for night shift. Read More; Custom Rubber Corp. article in Inside Rubber Magazine. Custom Rubber Corp. was featured in an article in the most recent Inside Rubber Magazine .IS 3400 (Part 2) :1995 Methods of test Technically for vulcanized rubbers: Part 2 Hardness equivalent with (second revision) minor deviation IS 13867:1993 Rubber standard do temperatures, humidities and times for the conditioning and time interval between vulcanization and testing of test piecesMooney viscosity, scorch and relaxation test of rubber compounds (ISO289-1 to 4) Mooney viscometer (MV2000E) . Vulcanization characteristics (MDR2000E) ISO6502. Determination of processing characteristics of uncured rubber compounds at the desired vulcanization temperature, including the scorch time, ts2 (maximum processing time to fill a .How to Perform a Tear Strength Test on Vulcanized Rubbers and Thermoplastic Elastomers. Written by Kayla Thackeray . ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test .

Rubber Vulcanization

Rubber Testing Products

Mooney viscosity test, the rotation of the metal disk is suddenly stopped and the rate of decrease of torque is monitored as a function of time. 4.1.3 Part C: Pre-Vulcanization CharacteristicsÑ This test method describes how pre-vulcanization properties may be measured. The viscosity of vulcanizable rubber compounds is

Rubber Standards

WEB6 de fev. de 2024 · The Arkle Challenge Trophy is the second race on day one of the Cheltenham Festival and takes place on Tuesday 12th March, 2024. Read More. Here you can check out all the latest odds, runners and Cheltenham tips for the Grade 1 2m novice chase, as well as learning everything about the history of the Arkle and how you can .

Rubber vulcanizing Tester warehouse|Rubber Standards